Seed treatments are an increasingly critical tool in farmers’ toolkits, protecting and supporting seeds through their vulnerable and critical germination and early emergence phases. Today’s seed treatments can be complicated recipes that include fungicides, insecticides, inoculants, colorants, polymers, nematicides and, increasingly, biologicals and biostimulants. Building a single highly effective seed treatment product from these various components isn’t as easy as simply combining ingredients in a blender, however. For each and every seed treatment it brings to market, seed treatment industry leader Corteva Agriscience invests in extensive product screening and testing. This ensures that, when multiple ingredients are combined into a treatment recipe, each component retains its efficacy, the complete recipe offers the practical functionality that farmers require, and the final product offers one more key deliverable:

“The seed treatment recipes we bring to producers needs to be better than the sum of all its ingredient parts,” says Rachel Woods, US Technical Services Manager with Corteva.

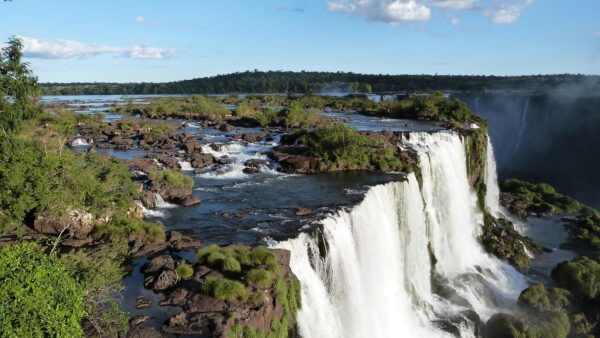

Back in 2015, Corteva invested in seed treatments as a product offering and built its first Center for Seed Applied Technologies (CSAT) in Johnston, Iowa. Part laboratory, part testing center and part seed treating plant, the Johnston CSAT was designed to allow the Corteva technical services team a facility to conduct comprehensive seed treatment development and testing at commercial scale. Since then, Corteva has expanded its CSAT capacity by building additional primary centers in Formosa, Brazil and Aussonne, France, as well as six regional CSAT laboratories. Whereas the three primary centers focus on large-scale development and testing of seed treatment formulations, the regional centers aim to meet the unique seed applied technology testing and trialing needs of specific growing regions.

“We develop and test hundreds of different recipe concepts each year,” says Woods. “As the different formulations come through our CSAT labs, we have the capacity to conduct a truly intensive review. It might be a great combination in theory, but if we see any separation in the slurry, any excessive build-up in equipment or any other issue that would negatively impact the customer experience, we send it back to the drawing board. Our goal and commitment — and what these facilities allow us to deliver on — is a positive customer experience.”

The development process testing starts by assessing growers’ needs and then evaluating novel active ingredients. Corteva sources the very best ingredients available both by leveraging its own R&D pipeline and by sourcing partner products. Once a concept recipe is designed, the testing phase evaluates every step a seed treatment must undergo from commercial treating facility to farmers’ fields. It begins in the lab, where the recipe is evaluated for slurry compatibility, application properties, dry down, flowability, abrasion and dust-off. Then it progresses through larger scale lab testing, first in an environmental chamber to mimic real world treating and planting conditions, and then in a larger scale test that mimics commercial application and planting environments. At all stages, the individual products must successfully function together and provide the right level of protection for each seed as it germinates. It’s a significant investment but one Woods says makes all the difference.

“Farmers have a really tough job. They need technology and solutions that work,” Woods says. “What drives me is helping identify the key gaps and opportunities that will make a difference for farmers. As a global leader in this space, we have the opportunity to innovate. It’s really exciting to deliver the kind of value that will help farmers be successful and give them added confidence for the crop year ahead.”