As inflation dominates the economy, some companies are choosing to forego certain seed tests. Experts agree that’s a risky choice.

The seed industry has seen better times than we are currently seeing. Much of this can be attributed to a stretched and fragile seed market. When dollars seem to be flowing out more quickly than they flow in, it can be tempting to try to sharpen one’s financial pencil by cutting out any additional costs. The big question is: is seed testing a ‘nice to have bonus’ or a ‘can’t skip it necessity’?

Multiple factors – virtually all outside of seed producer and seed companies’ control – have converged to challenge the seed sector.

“We are a global industry and rely on all world production areas,” says Amanda Patin, crop science director of business development for SGS North America, Inc. in Brookings, South Dakota, whichperforms agricultural quality testing. She points out that every part of the globe has been impacted in recent years by numerous issues. Just some include, she says, “an increase in weather-related production issues, war, increased supply and transportation costs and a declining and aging labor force.”

“The war between Russia and Ukraine isn’t helping matters,” agrees Sarah Foster, president and senior seed analyst at 20/20 Seed Labs Inc., which has locations in Nisku, Alberta and Winnipeg, Manitoba. “Prices and supplies have been affected. Of course, it depends upon local versus other international markets and they vary considerably. [But] I don’t see the situation improving until the war is resolved.”

The case for seed testing

Given the current challenges — especially the challenge of increased input costs — Foster says seed customers are looking for any possible assurance of some protection from crop failures, poor performance, and disease threats. They also need precise planting information.

“Many seed by units or by seed per acre, so purchasing the highest quality products ensures a return on their investment. Seed analysts can consult on a variety of tests that meet the needs within a reasonable budget. Seed testing is not expensive compared to all of the other input costs such as fuel, fertilizer, seed treatment and fungicides.”

Quinn Gillespie is the quality manager at Universal Seed LLC., which has locations in Oregon and Washington. In that role, she conducts purity, germination, in-process mill checks, moisture tests, tetrazolium testing, and research testing on organic and conventional seed treatment products. She also works with the AOSA-SCST (Association of Official Seed Analysts – Society of Commercial Seed Technologists) on the Communications and Publications Committee, the Executive Board, and the Referee Committee to help analysts conduct research for training and method validation studies for future rule proposals.

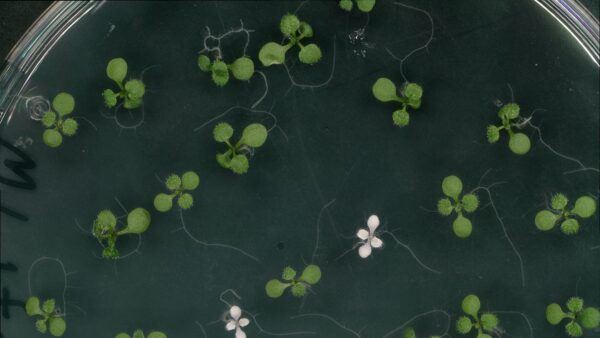

She says vigor testing can provide invaluable information for growers and seed buyers who need to know not just what percentage of their seed is viable but how uniform of a stand the seed has the potential to produce, including whether or not the seed can survive being planted early into cool soil, or how well it may fare during a wave of hot weather.

“Seed quality testing protects everyone, from the grower getting paid for their seed to the final consumer of the product,” she says.

With growing understanding in the marketplace about the value of seed testing, many seed customers are starting to demand seed quality proof to provide themselves with the best potential of securing a successful harvest.

Patin says it’s in a seed seller’s best interest to provide tests. “Test to show your seed has vigor and can withstand stressful conditions. Market your advantage. If you have more drought tolerant seed, test it and show that to potential customers: market it. If your seed is more tolerant to cold, talk about what makes your seed a better investment, show the customer and market it.”

Perhaps Patin sums things up best: “There are so many choices on the market. Seed is expensive; growing a high-quality crop has high input costs; and failure puts your customer out of business, as well as can give your product a bad name. Performing a few extra tests to show and demonstrate a high-quality product can make all the difference in the world.”

What is slowing uptake of seed tests?

As inflation dominates the economy and prices of everything from inputs to land continue to rise, some companies are choosing to skip optional seed tests to reduce costs. Ultimately, this decision hurts agriculture by allowing less-than-excellent seed into the market.

Gillespie says that the cost of testing is often a point of contention, even though the actual cost of the seed test comes backed with thousands of hours of experience and proven methods, the materials for which are not inexpensive. For those looking to market internationally, the cost of testing is negligible when considered against the alternative, she adds.

“Compared to the cost of seed arriving in another country and not meeting quality standards, the cost of seed testing before it leaves the dock is pretty minimal.”

The other concern companies often report is the time that testing necessarily requires. “Some tests can take nearly a month to complete, which can make it difficult to meet shipping dates at times,” says Gillespie. “During the busiest parts of the season labs frequently have some backlog as well.”

The reality of the situation, she says, is that when dealing with plants, each species has evolved and been bred to have certain behaviors. Some of them just grow at a slower rate. Waiting for full results is always worthwhile.

“Labs may conduct tetrazolium — quick viability — tests to get an idea of the potential viability of the seed, but this information is not suitable for labeling,” she says.

Opting not to perform quality standard testing could be an unwise business practice, says Patin. Scrimping on testing could ultimately allow poor quality seed to be sold to customers, resulting in product failure, decreased trust in one’s brand, dissatisfied clients, and potential loss of market share.

“Many seed quality tests are also required by contract agreements with trait suppliers. A company can lose their rights to use the technology and [it can] cause damage to a company’s reputation. The requirements are put into place for various reasons, not the least of which is to protect the tool (trait, technology) for future use. Spending a small amount of money upfront can be a huge advantage to the company as well as the industry,” says Patin.

Is the answer private labs?

A change Gillespie has noted over the last few years is that more private production and seed firms are looking to run their own lab capacity. In the Pacific Northwest, some growers and/or producers have added labs, or plan to add in-house testing capacity to their facilities in order to control testing independently.

She says some have sought accreditation through the National Seed Health System (NSHS) for phytosanitary visual inspection to reduce delays in getting phytosanitary certificates for shipments going overseas.

“If they have the space, it may be more advantageous to have a company lab to turn to for answers about testing and to incorporate the overall cost of the lab in with the company’s general operating costs to reduce the time delays that come with sending seed out for testing.”

The issue with this option, however, is a shortage of accredited seed analysts. The seasonal nature of the work can make it difficult to retain staff in labs. This reduces the overall number of analysts available to achieve the independent certification required for a lab to be authorized to conduct testing suitable for labeling.

“Analysts with insufficient training are not able to provide the same kind of uniform results as accredited analysts, and it takes a bare minimum of one to two years of work in a lab even for someone who has a degree in agronomy or botany,” adds Gillespie. “Seed testing is extremely specialized and not a course commonly taught in universities.”

Should seed regulation change?

Different jurisdictions require by law different seed testing.

To meet the grade requirements set out by the Canada Federal Seeds Act, all seed sold in Canada must be tested for physical purity, germination on all crop types, and true loose smut on barley.

“I agree with the [Canadian] system as it is now as it protects both the seller and the buyer,” says Foster. “However, I would like to see more tests accredited or — at the very least — protected by standard protocols and procedures that are monitored by proficiency programs.”

In the U.S., seed testing varies depending on what type of seed it is, the number of seed in unit, where the seed originated from, and where it will be sold.

“Tests required by law are driven at the federal level by the Federal Seed Act and at the local level (i.e., state),” explains Patin. “Agricultural seed is required to have a germination, purity, and noxious exam. Each state can have additional laws and requirements. The laws are in place to protect consumers, buyers, and sellers.”

Gillespie adds that many states have patterned their seed laws after RUSSL (Recommended Uniform State Seed Law) implemented by the Association of American Seed Control Officials (AASCO).

“The requirements for seed labeling are really very basic. For vegetable seed in packets, almost no information is required other than whether or not the seed meets the standards established in the Federal Seed Act.”

She sees room for improvement. “Especially for companies selling smaller types of vegetable seeds, or those that may be easily subject to contamination, purity information would also be beneficial.”