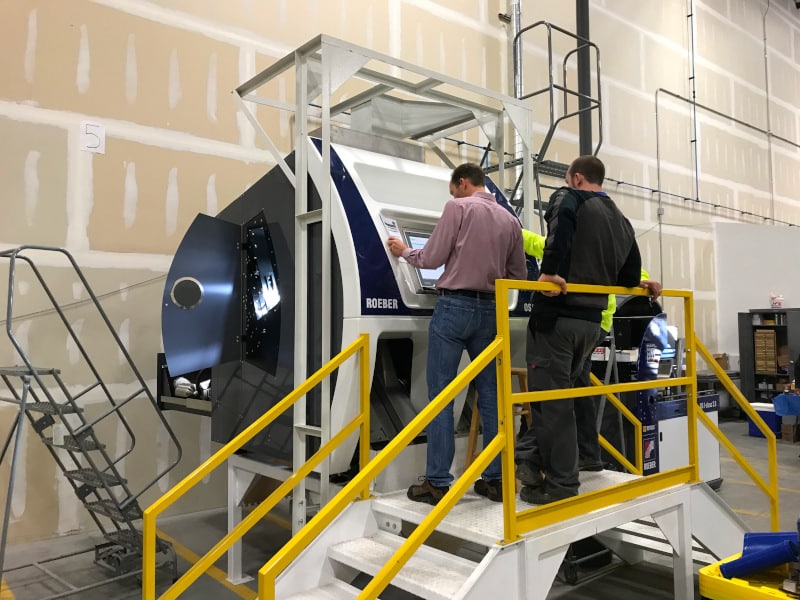

Buying cars over the internet is all fine and good, but there’s no substitute for testing conditioning equipment in person in a test lab.

The online world allows us to purchase all kinds of things without actually trying them out. I just read an article the other day about how car buying is going online in what’s being called the “Amazonification” of the auto market.

That’s all fine and good, but the world of seed conditioning is unique. Combining experience and knowledge with the ability to test and refine ideas in a lab setting is key to ensuring the viability of a project before a customer invests large sums of money. It’s what we’ve been doing at Premier Tech at our test lab in Grimes, Iowa, for several years.

Customers can bring in their own product and see the features in action, which helps to build trust and confidence in our equipment.

The proof of this approach is in the pudding, as they say; I think fondly of clients who we have been able to help solve a specific problem and then move them forward with a project they were unsure about.

I recall a recent client who ran their product through the sorting equipment at our lab and was able to make a difficult sort they could not make previously. Our color sorter allowed them to make that leap in their sorting capability that they had never achieved in the past. Transmission technology that is unique to the PETKUS OptoSelector allows for vision beyond the surface of the seed and enabled success in eliminating a key issue.

Another client visited our test lab to try out our treating equipment. The Petkus MultiCoater was able to provide a solution to the customer’s problem with the seed turning gelatinous and give him confidence to move the project forward — a combination of the MultiCoater and the Petkus fluidized bed dryer allowed it to be handled safely and flow smoothly after being encapsulated.

These experiences highlight the value of having uniquely advanced and specialized equipment that can provide solutions to specific challenges that so many seed producers face, not to mention a good facility to show them off.

By offering this level of testing and confirmation, customers can have greater confidence that their project will be successful and may be more willing to make the necessary investments.

Additionally, we know that having experience with a variety of seed types and chemical mixtures allows for greater adaptability to unique situations.

We’re in the process of expanding our testing capabilities by leasing a new building in Ankeny, Iowa, where we’ll have a full-scale Petkus color sorter, batch treater with chemical delivery system, gravity separator, and a fluidized belt dryer allowing clients to test out different equipment and refine their processes before making any large investments.

The new building will be larger and will allow us to house all our equipment in one location. Customers can come from around the country to get a taste of our hands-on approach to showing clients the possibilities they can realize by teaming with us on both larger and smaller projects.

The ability to test products in a commercial capacity and refine ideas and processes in a hands-on setting is a powerful tool to give customers the confidence they need to make that investment. Without testing, the purchase is a bit of a leap of faith, not unlike a new product on Amazon, but with a much higher risk.