Yield10 Bioscience, Inc. announced successful field testing of prototype lines of the oilseed Camelina sativa that have been programed to produce PHA bioplastics directly in seed.

PHA are natural polymers, prevalent in nature and fully biodegradable in the environment. Currently produced by fermentation of engineered microbes, PHA polymers also have applications in water treatment where they act as a zero-waste solution to nitrate pollution and as animal feed ingredients. Yield10 has a long history with and deep knowledge of PHAs and it believes that direct production of PHA in seed as a co-product with oil and protein meal has the potential to enable production of PHA bioplastics on an agricultural scale at costs in line with commodity vegetable oils to drive large-scale adoption in the plastics markets. PHA bioplastics could ultimately be used to manufacture a wide range of fully biodegradable consumer products.

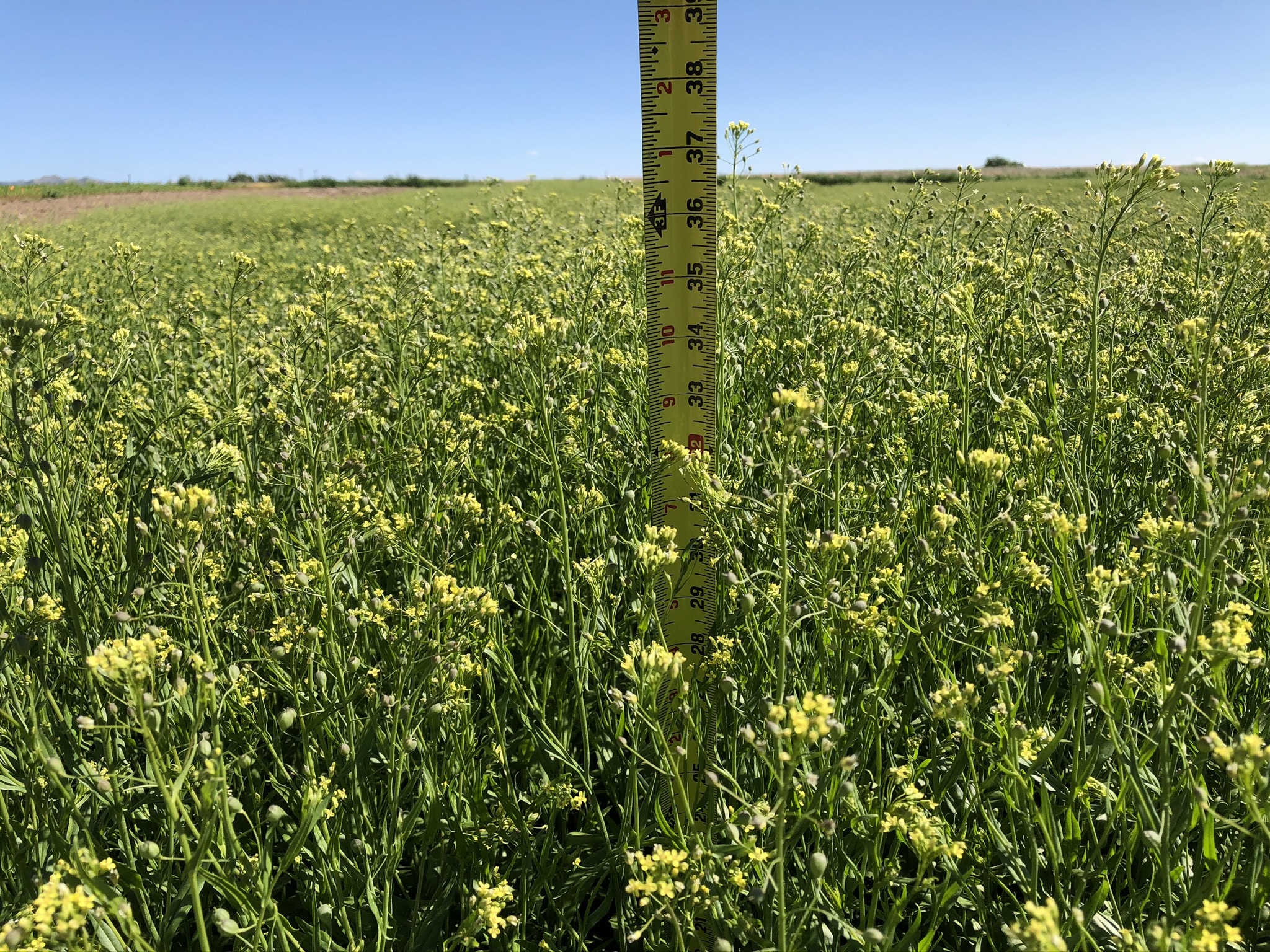

The prototype plants tested in these studies were programmed with microbial genes based on a recent patent filed for new technology developed by Yield10 researchers to produce Camelina seed containing high levels of PHA bioplastic suitable for field production. Several Camelina lines were grown in small plots at field test sites in the U.S. and Canada. Compared to control plants, the engineered PHA Camelina lines emerged and matured later but once established, exhibited good vigor, branching, flowering and seed set. All engineered PHA Camelina lines tested produced PHA in the seed. The levels of PHA produced in seed at the two different locations were consistent and measured up to 6 percent PHA of mature seed weight depending on the plant line tested, demonstrating proof-of-concept for field production of PHA in Camelina sativa using the new technology.

Based on these results, Yield10 has selected two PHA Camelina lines for larger scale field testing in 2021, pending the issuance of permits in the U.S. In addition to generating more data, Yield10 plans to determine the suitability of the lines for initial commercial activities. Each PHA application area has different price points and scale requirements and will have different PHA content requirements for commercial launch. Based on this, Yield10 believes that PHA content in the range of 5 to 20 percent of mature seed weight in Camelina would address the range of target applications. Yield10 plans to extract the PHA bioplastic from the Camelina seed for product prototyping, sampling and business development.

“It is truly exciting to reach this milestone in our effort to produce PHA bioplastic in the seeds of field grown Camelina plants,” says Kristi Snell, vice president of research and chief science officer of Yield10 Bioscience. “Our team has implemented several improvements to advance PHA producing Camelina lines to this important stage of development. Insights from our field tests as well as our expertise for increasing carbon flow in Camelina from our GRAIN platform are expected to enable us to make further improvements to increase yields of PHA per acre. Although not essential for initial commercial launch, our long-term technology goal is to increase the PHA content of seed to about 20 percent of the mature seed weight and combine that with advanced higher-yielding, herbicide-tolerant varieties currently in development to drive production costs as low as possible.”

“Our development of Camelina as a new platform crop to produce proprietary products is aligned with global trends to a low carbon economy. These include innovations in cash relay and cover crops for growers to reduce the environmental impact of commodity agriculture and the production of carbon negative products for food, fuel and plastics,” says Oliver Peoples, president and chief executive officer of Yield10 Bioscience. “Congratulations to our science team for achieving this critical first step towards commercial development of this technology.”

“We are executing our strategy to build strong cash flow to support the commercialization of Camelina PHA bioplastics. Our near term commercial efforts are focused on launching our Camelina business to produce oil for renewable diesel and as a fish oil supplement for aquaculture feed, and developing the business plan for the recently obtained rights to the Camelina omega-3 (DHA+EPA) replacement fish oil under our recent agreements with Rothamsted Research. Based on its level of development, we believe the drop-in fish oil replacement technology is currently closer to commercialization and could provide some of the resources we will need to develop PHA in Camelina,” says Peoples.

Evaluation of the results for additional traits tested in Yield10’s 2020 field tests is currently ongoing and the Company anticipates providing updates as data becomes available.