Why USC’s Drive To Continually Innovate Has Positioned The Company As The Industry’s Equipment Leader For 20+ Years.

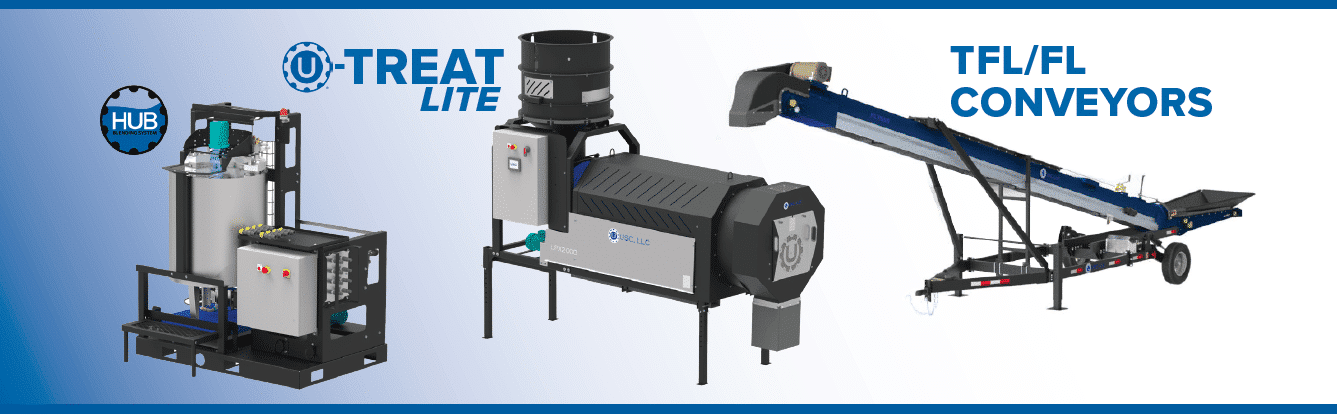

USC takes pride in continued efforts to partner and collaborate with seed and treatment companies industry-wide, bringing the most innovative, user-friendly and affordable products to operations across the country and spanning the globe. For more than 20 years, USC has researched, developed and improved upon equipment ensuring each customer benefits from their investment. Innovations over the past year include the release of the LPX LITE Automation Platform, the Field Loader Conveyor Series, and the recently-developed HUB Blending System.

USC’s exclusive automation platform provides a consistent, error-free and efficient system ideal for multi- tank and auxiliary device users. U-Treat LITE recipes allow the operator to pre-set application rates, select product tank(s), and determine if auxiliary devices are needed, virtually eliminating errors. U-Treat LITE offers more flexibility in treatment packages for those who separate products into individual tanks and customize treatments on a per-customer basis. Simply select a pre-set recipe on the Startup Wizard and get to treating!

LPX LITE AUTOMATION PLATFORM

- Automates up to four volumetric metering pump stands.

- Automates seed metering with Seed Wheel or Loss in Weight gate.

- Supports up to 500 customers, seed profiles, chemistry profiles, and recipes.

- Saves up to 5,000 reports viewable on-screen or downloadable to .csv file.

- Features a 10” touchscreen for easy operation.

- Can be controlled remotely via a mobile device.

- Increased flexibility for auxiliary devices with two sets of independent controls.

FIELD LOADER CONVEYOR SERIES

Designed with the user in mind, USC’s patent pending Field Loader conveyor brings convenience, ease-of-use and safety features together in a revolutionary, one-of-a-kind conveyor.

- Trailing or standard undercarriage.

- Stainless or carbon steel tube and undercarriage options.

- Multiple power options.

- 7,500 bu/hr at 20 degree incline; 30’, 40’ and 45’ available lengths.

- 10HP Farm Duty electric motor or gas powered hydraulic pack.

- Easily back trailing conveyor under semi or bulk bin (trailing option).

- Wireless remote for wheel hydraulics, easily lower tail section (trailing option).

- Tow from discharge end for easier conveyor inlet placement (trailing option).

HUB BLENDING SYSTEM

Introducing USC’s latest treating addition: the HUB Blending System! Operators and industry influencers collectively reported a need for a more accurate and affordable blending system. Once again, USC provided a solution! USC’s HUB is compatible with U-Treat V4 and its configurable and flexible plug-&-play features make it the most saught after blending system.

- Blend up to 20 ingredients at a time.

- Flexibility with configurable 8- or 16-automated batches; remaining fields available for dry or liquid “hand-add” application(s).

- Dry or liquid ingredients are applied through suspension and USC’s rapid agitation design.

- Real-time ingredient blending.

- Transfer pump with air purge transfers products to treating system.

- Plug-&-Play system: minimal installation required and installed at the USC plant. Simply connect the transfer pumps to keg/tote and import manifold.