For more than 20 years, CSP labs has been providing the fruit and vegetable industry fast and efficient testing of bacterial fruit blotch (BFB) of watermelon, providing added reassurance to the cucurbit (watermelon, melon, squash) industry and its growers.

First observed in 1965 at a United States Department of Agriculture plant introduction station, BFB caused seedling blight within infected seeds. It wouldn’t be until nearly 30 years later, in 1994, that the detriment of the bacteria would be again realized. BFB caused widespread damage across the states of Florida, Georgia, Indiana, South Carolina, and Texas. Due to the water splash and contact borne nature of the bacteria, the outbreak quickly spread and the poor sanitation practices and lack of seed testing, at the time, made the bacteria nearly impossible to contain once introduced into a field or transplant house.

Because of limited testing to identify infected seed lots, lawsuits were quickly filed against many seed producing companies and watermelon, a susceptible crop, seed sales were suspended. This crisis would be the turning point in the industry’s directives for testing seeds for BFB.

“Once infection occurs, the plant is a complete loss,” says Kiran Mani, who serves as the manager of CSP’s Seed Health Lab. “And infected seed is the primary source of infection.”

It is thought that the seeds become infected by coming into contact with infected fruit tissue. While it isn’t known if the epidemic initiating pathogen resides inside the seed coat or on the seed coat, itself, what is known is that none of the seed treatments commonly used to clean the seed surface are 100% efficient in eradicating the pathogen.

To mitigate the risk of BFB infection, commercial seed production fields utilize growing management protocols and rotation. Seeds are produced in dry and cool climatic locations with no bacterial fruit blight history; all fields are rotated to non-cucurbit crops, and only tested disease-free seeds are used in fruit production fields.

Seed health testing further reduces the risk of epidemics, and today’s industry standards are to test between 10,000 and 30,000 seeds from each seed lot to help ensure the production of disease-free transplants.

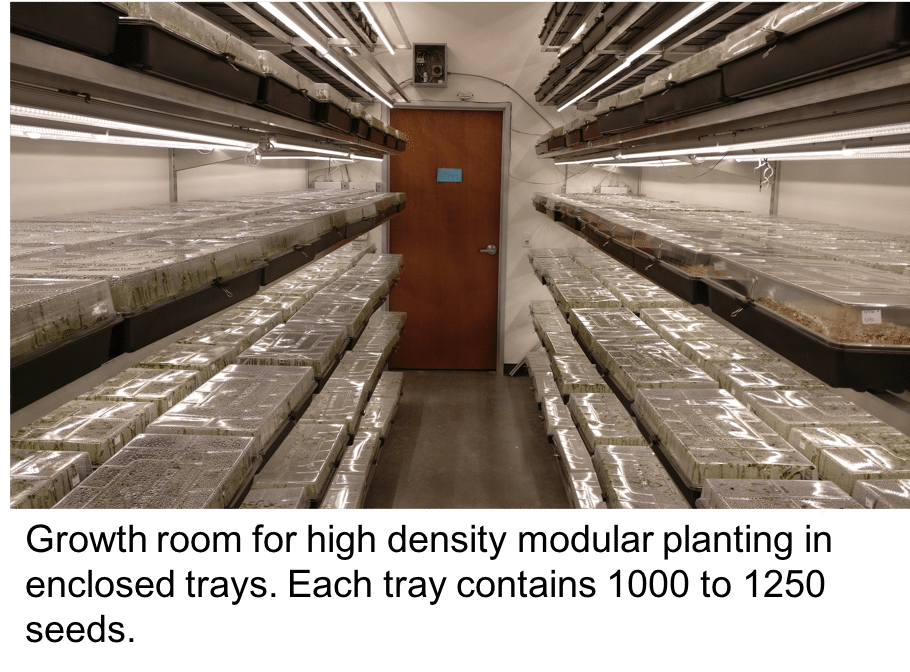

To meet these standards, CSP Labs has developed the Seedling-PCR test. The test produces results in 12 days, making it the fastest greenhouse or growth chamber test available to meet the 10,000 to 30,000 seed requirement.

“We run between 90 and 100 tests a week,” shares Nilesh Maharaj, “that’s about 1.2 million seeds. Anyone can run this test, CSP did develop it, but it isn’t proprietary, but we [CSP Labs] are the only ones offering it.”

And, because the space requirements are modular (enclosed 10 inch by 20 inch trays) there is minimal wait time to begin a new test, which can be an issue with the BFB grow out test that requires the use of an entire greenhouse.”

Due to good seed health testing and sound production practices, bacterial fruit blotch losses have lessened, however, sporadic outbreaks still occur in the United States, Australia, Brazil, China, Israel, Japan, and Thailand, prompting companies to add a disclaimer stating that although seeds have been tested, they are not guaranteed to be disease-free.