Advancements in polymers, the application process and training opportunities reduce dust from treated seed.

Farming is dirty work — at the end of a long day, returning home from the fields covered in everything from sweat and manure to ticks and stick tights, and of course, dust.

Dust is inevitable. It’s everywhere, but a focus on pollinator health has led industry efforts aimed at specifically reducing the amount of dust released during planting when treated seed is being used. It’s a proactive pollinator health step, and serious strides have been made.

Palle Pedersen, head of Syngenta Seedcare product marketing, says the real work to reduce dust through seed treatment applications began more than 10 years ago in Europe.

“There is no real documentation that seed treatments are causing pollinator health issues, but we want to be sure when we are in the field, whether using a seed treatment or spraying, that we are a good steward of the land for everyone around us, including the pollinators,” Pedersen says.

Most recently, the biggest impact comes from improvements to the polymers and application process. But other improvements such as filtering dust from planter boxes or even directing the planter exhaust air to go down instead of up are also noteworthy.

Application Efforts

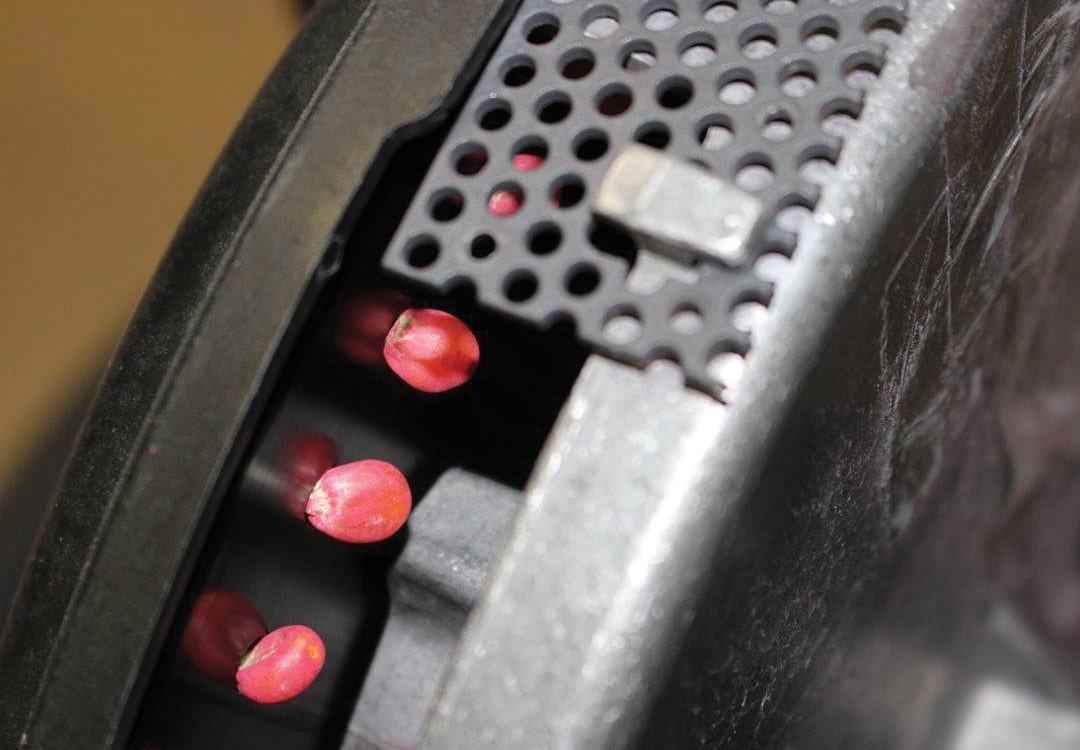

A more precise application process for applying the treatment to each individual seed has been a key area of focus.

Andy LaVigne, American Seed Trade Association president and CEO, says the process has moved from a highly variable application to one that is extremely contained and controlled.

To help provide a visual, LaVigne says: “Imagine a small machine that is enclosed and looks sort of like a cement mixer so it contains all the chemicals and applies the treatment in exact amounts to each seed as they move around the drum.”

This also keeps applicators safe, and the process has been perfected during the past several years to a point where it is extremely effective.

“We can apply the treatment with an accuracy of plus or minus 5 percent, and when you’re talking about milligrams, that is extremely accurate,” Pedersen says.

Before, Pedersen says applications were based on volume, or fluid ounces per 100 pounds of seed, so the seed size and shape wasn’t taken into consideration.

Other advances are new polymers, or sticking agents, being applied to the slurry. “These additives help the treatment dry faster and help it stick to the seed surface better,” Pedersen says.

Of course not all seed treatments are applied by the distributor. These efforts must trickle down to retail applications, as well. In fact, Pedersen says two-thirds of soybeans are treated at a retail location instead of a major seed supplier. It’s important to make sure the process is closely monitored.

“Syngenta offers services to help customers be sure to apply the right amount of treatment. You want to be sure you are working with a company that is committed to this effort,” Pedersen says.

Education is important, especially for those operating the application equipment.

“A key part of ensuring the system is as efficient as possible is that applicators are highly trained,” says Richard Gupton, senior vice president of public policy and counsel for the Agricultural Retailers Association.

Those professionals are trained to apply treatments that are customized to a farmer’s particular needs. “They can tailor it to treat for pest threats or other threats to the plant, but again, it’s highly automated, so we’ve greatly reduced the risk of error there as well,” Gupton says.

While significant resources have been invested to reduce dust from treated seed, there’s still room for improvement.

Opportunities for Improvement

One such area that companies continue to focus on is how to develop a more consistent seed conditioning process before the treatment is applied.

“There is a lot of dust involved when the seed is harvested with the combine, and a much of it sits on the surface of the seed, which makes it more difficult for a treatment to be effectively applied,” Pedersen explains.

In prepping for treatment, seeds must be conditioned, or cleaned, after harvest.

“It’s a very important part of the process,” Pedersen says, noting that seeds can be harvested from many countries and then shipped to one plant for treatment, or to retail for treatment. “We need to be sure the seed is prepared properly before it ever gets to that point.”

The wind is also a factor that cannot be ignored.

“We can’t control the wind, or droughts, or other conditions that create dust in the field at the time of planting,” Gupton adds. “Our job is to create policies that manage risks and ensure farmers have the tools they need to manage this process.”

Pedersen acknowledges that there are many variables that must be managed, but the industry is working as a whole to ensure the technology remains safe.

Collaboration has been critical to the success. Farmers, equipment manufacturers and seed companies are all working together to make the biggest impact.

“When we come together and can share expertise and resources, we avoid duplication and reduce waste so the work gets done much faster,” Pedersen says. “It’s nice to see that level of cooperation is possible even among competitors within the industry.

“Seed treatments are very commonly used, and when done correctly, they do an outstanding job of delivering targeted solutions with minimal risk to pollinators and the environment.”

Gupton adds that educating others is also important. While most are aware of pollinator health issues, not everyone is well-versed about specific best management practices when it comes to working with treated seed.

“We’re working to make sure the message is shared to everyone. Our members want to operate in a safe way to protect both human health and the environmental health,” Gupton says. “That means continuing to share information as it’s updated so we’re as informed as possible.”

An important resource is the Guide to Seed Treatment Stewardship, which provides best practices about topics ranging from labeling, transportation and storage of treated seeds to selection and planting.

“The guide is updated every few years to make sure the information is up-to-date and accurate,” Gupton says. “Our goal is to make sure as many tools are available to the industry as possible, developed by using accurate science, based on real data and not theoretical modeling.

Future Goals

It’s important to note that because of these proactive efforts here in the United States, there haven’t been any significant issues with dust off clouds from planting treated seed impacting pollinator health, but that doesn’t mean it’s not worth noting.

“These are proactive efforts, and recently, we’ve seen improvements every season, whether in new, more effective polymers, or in the way the seed is planted,” LaVigne says. “Of course, we know zero dust is not possible.

“Just moving a planter through a field without using treated seed is dusty. So, our goal is to minimize dust as much as possible, and we continue to make advancements in that area.”