Welcome to Seed World! We have recently updated our site to bring you seed news from across the globe, in one convenient location.

Read news tailored to your location by selecting from the Global dropdown above.

Benon Lorenzana’s journey from a small village in the Philippines to leading breeding teams in North America is not just...

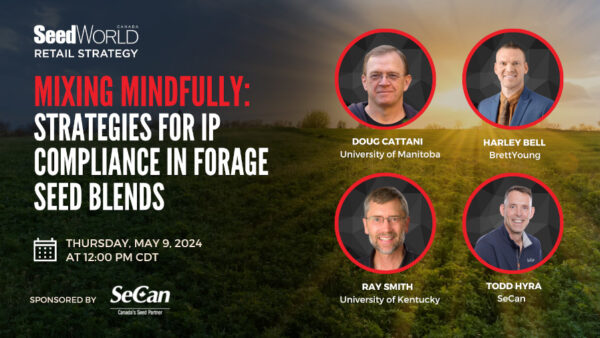

As the demand for customized forage blends continues to rise, so does the importance of respecting the intellectual property rights...

We sat down last week for an interview with the incoming president of the National Association of Plant Breeders, J.D....

At the recent meetings of the Prairie Grain Development Committee, Seed World Canada sat down with Howard Love, lead scientist...

The Canadian Food Inspection Agency recently launched its 2024 Seed Regulatory Modernization (SRM) winter consultation and survey. The first consultation...

As she wraps up her stint as chair of the Prairie Grain Development Committee, the owner of Sheri’s Ag Consulting...

Increasing grower adoption of new genetics is a necessity, but the way to do it lies in emphasizing its importance...