Welcome to Seed World! We have recently updated our site to bring you seed news from across the globe, in one convenient location.

Read news tailored to your location by selecting from the Global dropdown above.

When it comes to innovation in the area of biotechnology, few voices carry as much weight as Norm Sissons, a...

Gurcharn Singh Brar is a wheat breeder whose path meandered from the breadbaskets of Punjab, India, to the sprawling fields...

Today is a great day to get to know YOUR Seed World editors… all four of them. Though you likely...

The executive director of the Canadian Seed Growers’ Association sat down with Seed World Canada’s Marc Zienkiewicz to make the...

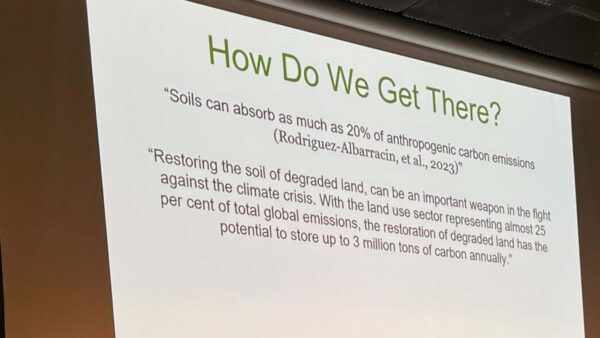

At the recent meetings of the Prairie Grain Development Committee, Seed World Canada sat down with Howard Love, lead scientist...

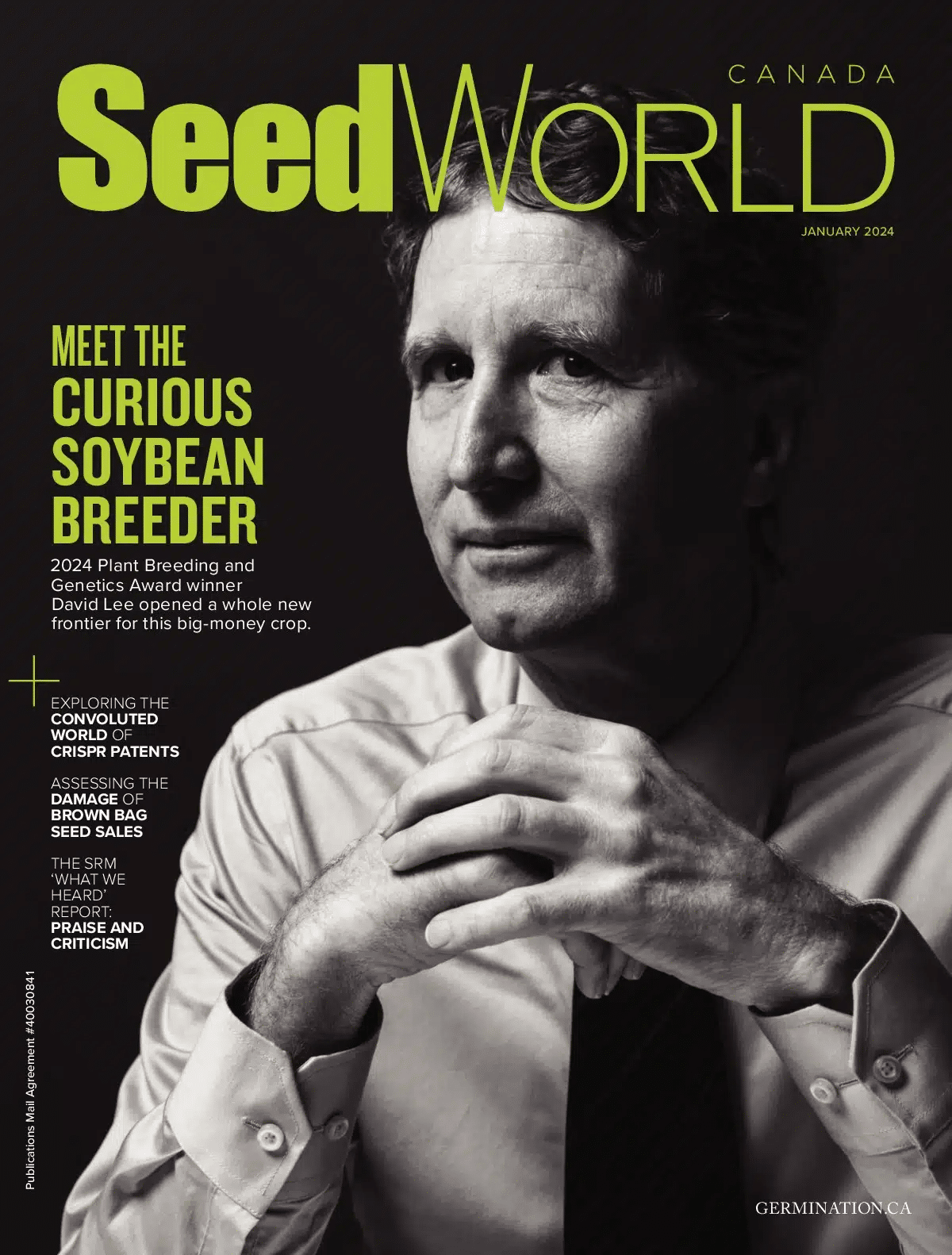

The Canadian Food Inspection Agency recently launched its 2024 Seed Regulatory Modernization (SRM) winter consultation and survey. The first consultation...

As she wraps up her stint as chair of the Prairie Grain Development Committee, the owner of Sheri’s Ag Consulting...

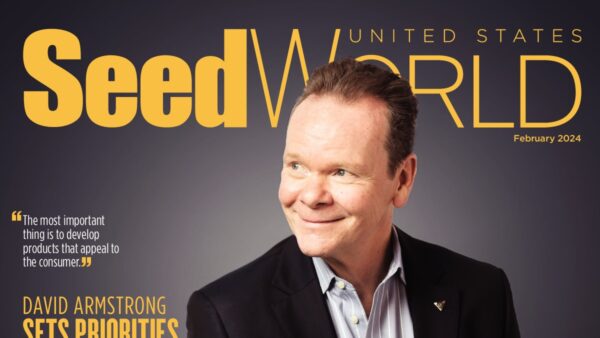

Increasing grower adoption of new genetics is a necessity, but the way to do it lies in emphasizing its importance...