USC’s patented and proven treating technologies exemplifies the importance of investing in equipment that does the work for you

If you’ve ever wondered how exactly a seed treater treats seed, you’re not alone. Seed treaters are uniquely simple machines that serve a very important purpose. While seed and application treatments are imperative to the seed treating process, they require the correct machine and technology to bring them together accurately and responsibly.

There a dozens of considerations and variables factored into the treating process, including seed type, weight, application best practices, metering methods, timing and automation to name a few. For more than two decades, USC’s treating equipment has shaped the way seed and treatment come together.

Here’s a detailed look into the treating process, and how USC’s patented technology continually provides precision to the overall treating equation – saving you time and resources, run after run, year after year.

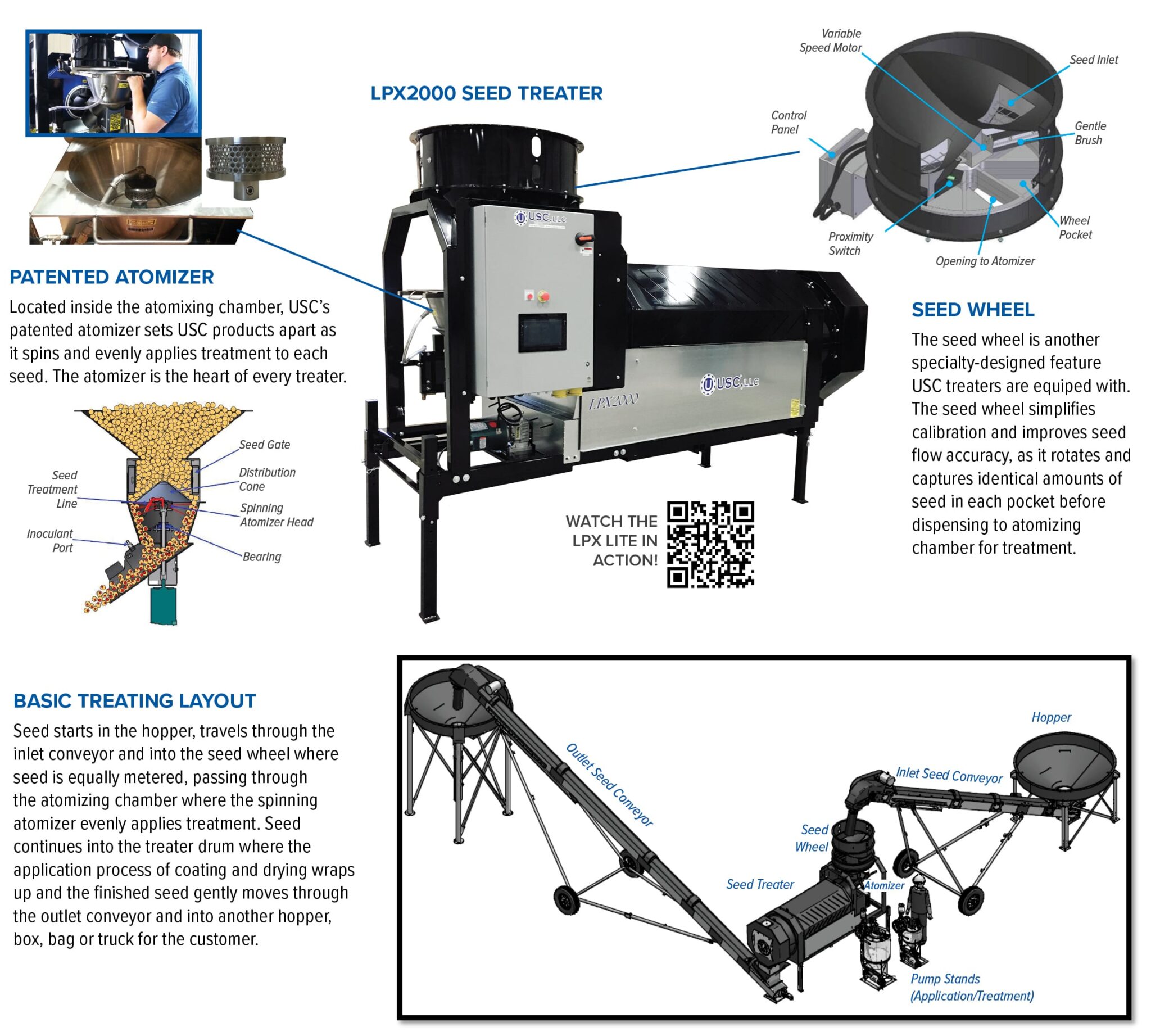

Patented Atomizer

Located inside the atomixing chamber, USC’s patented atomizer sets USC products apart as it spins and evenly applies treatment to each seed. The atomizer is the heart of every treater.

Basic Treating Layout

Seed starts in the hopper, travels through the inlet conveyor and into the seed wheel where seed is equally metered, passing through the atomizing chamber where the spinning atomizer evenly applies treatment. Seed continues into the treater drum where the application process of coating and drying wraps up and the finished seed gently moves through the outlet conveyor and into another hopper, box, bag or truck for the customer.

Seed Wheel

The seed wheel is another specialty-designed feature USC treaters are equiped with. The seed wheel simplifie calibration and improves seed flow accuracy, as it rotates and captures identical amounts of seed in each pocket before dispensing to atomizing chamber for treatment.