What started as a small seed breeding business is now the heart of innovative seed-applied technologies at Bayer CropScience. In 2015, Méréville celebrates its 100th year anniversary – time for a recap.

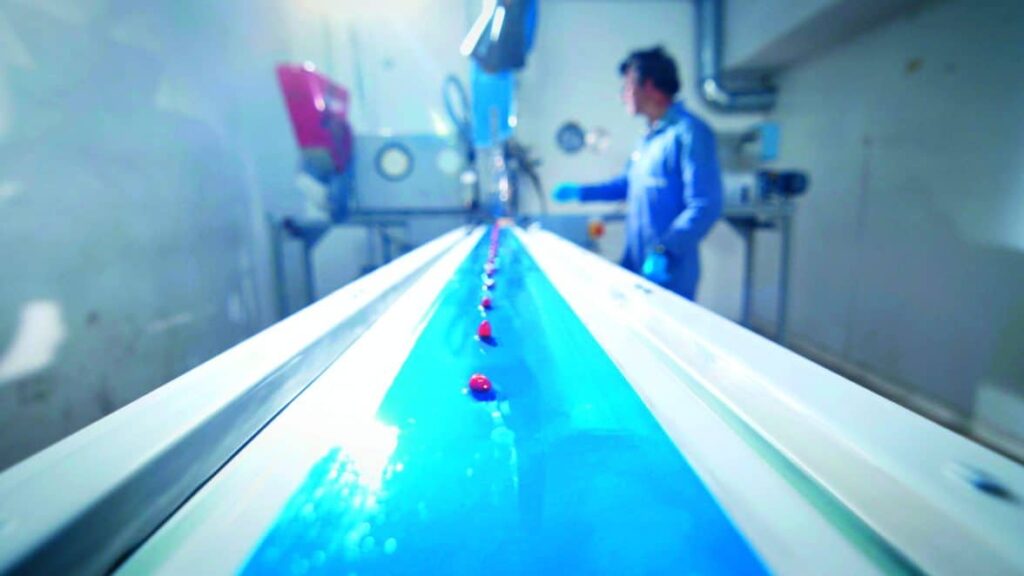

Outside of Paris, approximately 70 km from the French capital, a team of around 40 people work on formulas for seed coatings – recipes that are crucial for the treaters, planters, and growers across the globe. There can be between 10 and 15 specific film coatings for one type of seed surface. And the huge variety of coatings is constantly evolving due to new innovations that enable seed-applied products to better stick to the seeds, controlling dust-off and the abrasion of additives.

Huge business potential

What initially started in 1915 as a seed breeding business of wheat, emerged quite quickly into the sugar beet seed business due to expertise and business potential. George Martins breeding business of sugar beet took off and soon the first products, Céres Number 1 and Number 2 were launched. Céres, in the ancient Roman religion the goddess of agriculture, did not only serve as the name of the company itself, but also as the first brand of sugar beet varieties that Céres sold.

And still today, in 2015, the Bayer SeedGrowth Coatings facility in Méréville not only commercially treats sugar beet seeds but also develops new coating solutions for this crop. “The sugar beet seed is a really complex seed,” explains Marc Andrieux, Global Head SeedGrowth Technology, Services and Coatings at Bayer CropScience. “With its irregular shape, which resembles a star, planting the sugar beet seed precisely is pretty difficult. Céres was the first company in the world that invented and patented the pelleting process in 1946.” And today the formula of the pellet is still developing constantly, having positive effects on germination, drilling, and efficient planting in the field. After the first steps in planting and sowing technology, Céres invested in the seed protection business – in film coatings.

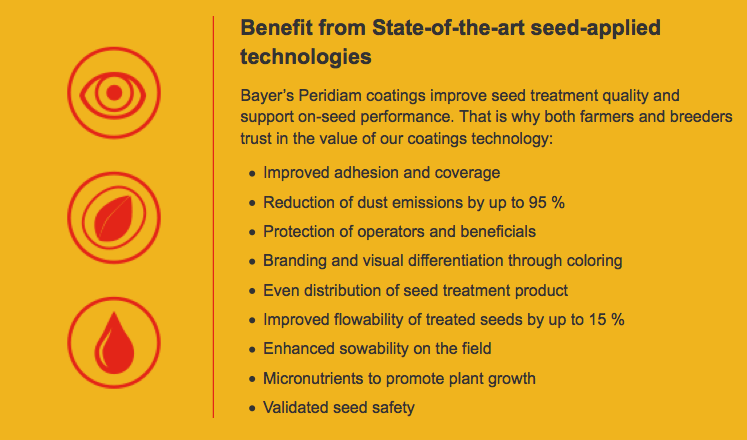

The flagship brand, Peridiam, which was launched in 1987, is still on the market with a growing product range, including Peridiam Evolution and Peridiam Ferti.“It’s a constant challenge to develop coatings to protect the seed, having the additives stick to it and making sure that germination, sowability, flowability, and dust control are tackled,” says Marc Andrieux.

All competences under one roof

In 2002, Bayer acquired the entire set of activities of Céres. With the launch of the competence brand Bayer SeedGrowth in 2013, Céres also moved under the brand umbrella with its name. “With this dedicated integrated center, we can not only develop but also produce and market film coatings. This efficiency is quite important due to the short life cycle of coatings in this dynamic business,” explains Marc Andrieux. The development of a fungicide or insecticide may take up to 10 years; however, the product will stay on the market for 10 to 20 years. That differs in the film coating sector, where besides a quite brief development of 2 to 3 years until market rollout, the lifespan of a coating is just about 5 to 6 years.

“To balance the stickiness and the flowability is one of the main aspects in the development of film coatings,” says Marc Andrieux. And that’s what Marc Andrieux and the team in Méréville are working on – the right recipe that blends all perfectly and stable. The farmer’s high yield is the seed company’s efficient processing. These critical parameters are evolving more efficient with film coatings as well. Having the right coating shortens the time of application and the packaging of the bags. This gains time and reduces costs effectively up to 5 %. “Take an airplane: if it has the right shape and the surface is smooth and clean, the machine is faster, arrives earlier, and saves fuel. This also applies to film coatings and that’s why the perfect recipe is so important,” explains Marc Andrieux.

Interview with Marc Andrieux

SAFETY FIRST

Sowability, flowability, and dust control are three challenges the industry for seed-applied technologies has to master today. Bayer SeedGrowth Coatings steps up to the plate. The facility, based in Méréville, France, is specialized in developing new seed coatings. Read why Marc Andrieux, Bayer CropScience Head of SeedGrowth Technology & Services, Coatings, is so positive about coatings and why they are such an important factor when it comes to sustainable agricultural practices and product stewardship.

Mr. Andrieux, why do seed coatings and product stewardship go together?

Marc Andrieux: “When we talk about stewardship we also need to talk about dust. Dust always accompanies seeds. One example of how stewardship is practiced at Bayer comes from the company’s successful efforts to limit dust-off through improved formulation, through tailor-made film coatings and their professional use by our customers.”

Could you please describe this in a little more detail?

Marc Andrieux: “We want to keep all the product on the seed. Seed coatings themselves are designed to be versatile, they need to be compatible with the other products applied to the seed. In the end, we want the final product to be safe for the seed, safe for the operator and safe for the environment.”

How would you summarize the benefits of coatings in just one sentence?

Marc Andrieux: “The idea in the end is that the farmer can simply plant the seed, everything needed for the seed to grow well will remain on the seed surface and flow precisely into the ground. That is in fact the big benefit of seed coatings.”

Are there any new developments in the pipeline?

Marc Andrieux: “When we develop new products we try to consider the needs of the global market. And we see there is a need for even more film coatings with even more functions. That’s why we plan to launch ten to fifteen new film coating products over the next five years. These new solutions will include products targeted for small grains, corn, rice, and soybean.”

You want to know more about cutting-edge film coatings and why they are crucial for successful farming? Visit www.seedgrowth.bayer.com and learn more about Bayer SeedGrowth Coatings.