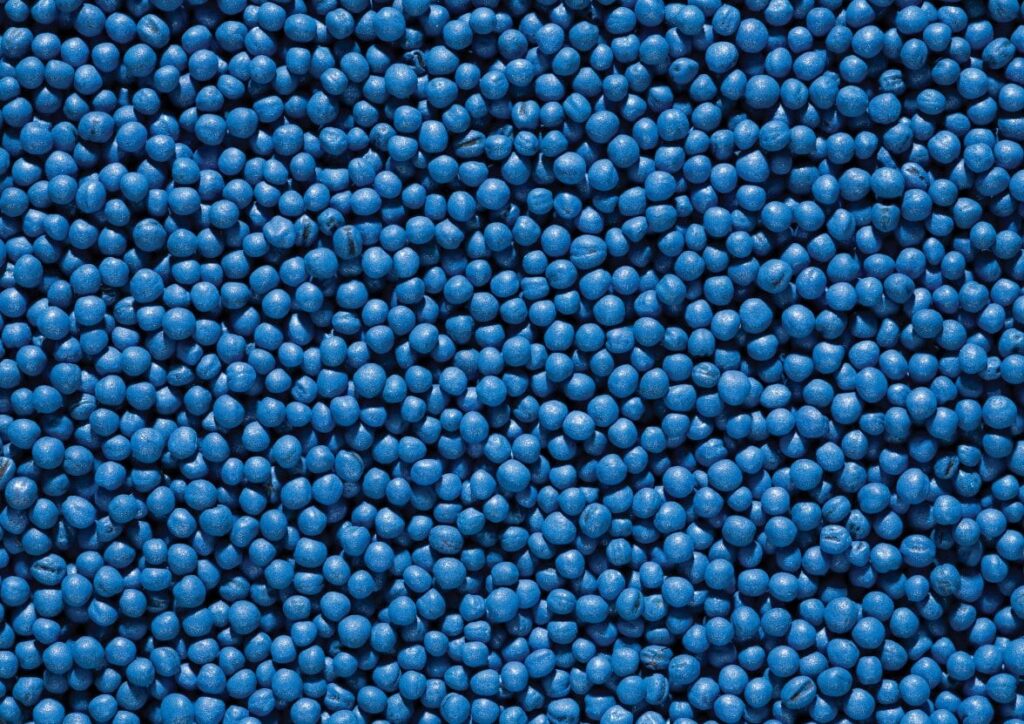

New ESTA scheme addresses the need for quality assurance during the application of plant protection products to seed and subsequent handling of treated seed.

I n order to get a clear picture of when and why the European Seed Treatment Assurance (ESTA) scheme was set up, we need to go back in time a bit. On May 15, 2008, the German Federal Office for Consumer Protection and Food Safety (BVL) — responsible for the authorisation of plant protection products in Germany — decided to suspend the authorisations of defined insecticides used for seed treatment. The use of seed treated with these products was suspected to be the cause of an unusually high mortality rate of honeybees observed in a small area in southwest Germany that year.

Following investigations, it was confirmed that the bees had died from exposure to clothianidin, an active substance contained in a plant protection product (PPP) used as seed treatment for maize in Germany. The main causal factor was identified as incorrect application of the PPP, in combination with the specific pneumatic sowing equipment used, special weather conditions during sowing and a specific dosage rate that had been compulsory to fight the spread of diabrotica, a pest currently spreading throughout Southern and Central Europe.

The results of the analysis carried out indicated that unusually high quantities of seed treatment dust had been emitted into the environment during sowing, as a result of the abrasion of corn seed treatment from batches that had not been correctly applied to the seed. The drift of the abraded material was amplified by the use of certain pneumatic corn-sowing machines that allowed the material to be dispersed into the air, as well as by the dryness of the soil and strong winds during sowing. This dispersed the seed treatment’s active ingredient to neighbouring fields frequented by bees.

“The bee incident in Germany underlined that the quality of the seed treatment application is essential to help to avoid serious

adverse impact on the environment and that each part of the chain needs to assume specific quality assurance responsibility,” ESTA manager Amalia Kafka says.

Following this incident, in 2009/2010, the European Seed Association (ESA) started developing the ESTA scheme for quality assurance during the application of plant protection products to seed and the handling of treated seed. The scheme was developed with the collaboration of the seed industry, the crop protection industry and the national authorities.

Taking Aim

“ESTA combines a number of elements to guarantee professional, high-quality seed treating applications, defined quality reference values with a uniform testing protocol, safe use information and respective labeling for users. The ESTA logo may be awarded to companies complying with the scheme and its standards and audited and accredited accordingly,” Kafka says.

It provides a quality assurance system to ensure that the process of treating seeds and the resulting treated seed meet requirements defined by legislators and industry. Seed treatments and their application combine precision and low doses of active ingredient amounts to maximize efficacy and ensure minimal environmental impact.

James Wallace of the U.K.’s Dalton Seeds, a former board member of the Agricultural Industries Confederation (AIC) and member of the ESA STAT Working Group, is very clear about the ESTA system.

“The seed industry must recognise [that] society needs to be sure pesticides are used correctly and safely for people and the environment. The EU has established controls for the application of foliar applied chemicals and the Commission Draft Guidance Document proposes similar monitoring of seed treatment applications. ESTA provides the seed industry with a scheme for ensuring these controls are appropriate for the effective and efficient application of PPP and are not a burden on our businesses.”

Kafka adds: “Companies certified to the ESTA standard reliably treat seed with plant protection products, resulting in quality products (treated seed) for the ultimate user — farmer, grower, plant raiser or contractor. The ESTA certification provides key assurances of full control of the processes for treating seeds; continual improvement of processes and standards; and adequately and well-trained personnel. ESTA certifies that only seed meeting agreed quality standards is being put on the market.”

ESTA as an independently-audited trade assurance scheme provides a cost-effective way of ensuring high standards of product application to meet public and customer demands, Wallace adds. “It’s cost-effective to the industry by ensuring the requirements are practical and not a burden. [It is also] cost-effective for regulators, by using an industry-operated scheme subject to independent auditing to ensure compliance.”

ESTA’s Benefits

Companies benefit greatly from joining the ESTA scheme. Klaus Schlünder, head of business development, oil crops for KWS says, “The ESTA membership [shows] that the seed industry cares about quality, which means it cares about the environment and farmers as end-users. The benefit KWS has received is to deliver seeds with high-quality seed treatment, which is controlled and certified within the scheme by an independent organisation and that the scheme is accepted by the authorities.”

Wallace notes there are numerous benefits to the ESTA system:

- Assurance of top-quality seed treatment application: Accurate and consistent application of seed treatment products is essential for both efficacy and the safety of operators and the environment. Ensuring this is achieved and that it is continually being improved is vital for a successful seed business.

- Independent auditing to assure customers and the public: Reassurance that the application of pesticides is done safely and correctly is important to customers and the public. ESTA provides for certification of seed treatment facilities by independent professional auditors.

- Securing the future supply of seed treatment products: By providing assurance of professional application, authorities can approve new products with the knowledge they will be applied correctly. The draft EU guidance document proposes the establishment of schemes for the national certification of seed treatment facilities.

- Avoid implementation of costly regulations: If the authorities are concerned about the safety of the application process, they could impose costly regulations on the seed trade. Assurance schemes such as ESTA have been effective in avoiding the imposition of cumbersome regulations within agriculture

- Ensure the free movement of treated seed within the EU: ESTA will provide EU-wide accepted standards for seed treatment. “This is especially important where small quantities of seed are treated in one country for wider distribution throughout the EU, for example oilseed rape and vegetable seeds,” Wallace says.

Applying for ESTA Certification

The way in which a company applies for ESTA certification depends on the country. In France, Germany, Poland, Spain and the U.K., ESTA is operated by national agents. If a site is located in one of these countries, the company should contact the national agent of its country. The agents are as follows:

- France – Union Française des Semenciers (UFS)

- Germany – SeedGuard

- Poland – Polska Izba Nasienna/Polish Seed Trade Association (PIN)

- Spain – ANOVE

- U.K. – Agricultural Industries Confederation AIC

The national agents have the specific infrastructure, knowledge and competence and cooperate with ESA in the implementation of the ESTA scheme in their territory.

The national agents deal with:

(i) the acceptance of ESTA Certifying Bodies (CB); and

(ii) the licensing of the ESTA trademark to ESTA-certified treatment sites located in the territory.

“If a site is located in any other country, it should contact an accredited CB and plan the audit. After the successful audit the CB will send the ESTA Certificate to ESA and then the site will need to sign the Standard License Agreement with ESA, which will allow the use of the ESTA logo,” Kafka says.

German seed company KWS has recently joined ESTA.

“Seed quality has always been an important issue within KWS, so when the [opportunity]was presented to get an independent, industry-driven system in place, it was clear that KWS should join the system,” Schlünder says.

For KWS, the advantages included:

- Process-driven audit and certification;

- Acceptance of the system by the authorities;

- Sustainable approach as continuous improvement is one important pillar in the scheme;

- Scheme is more flexible in implementation and application of new technologies, which is a requirement for all participants.

As soon as a company decides to join ESTA, several changes need to be made within the company.

“Within KWS we have an ongoing QAS (quality assurance scheme) that is regularly audited under ISO 9001. By implementing the ESTA scheme we were obliged to adapt certain parts to the new checklist and implement further testing methods like the Heubach Test in our laboratory, together with the necessary training of the personnel involved. Other process steps had to be modified in respect to the supply chain management to fulfill the ESTA requirements,” Schlünder says.

Uptake by Legislators

“The ESTA scheme has been very well-received by the EU Commission and the member states. The second draft of the guidance document for the authorisation of plant protection products for seed treatment refers to guidance documents that should be used to assess the quality of the seed treatment process and the quality of the treated seed. ESTA is acknowledged as one of these seed treatment process certification systems,” Kafka says.

ESTA has been designed to be compatible with the national quality assurance systems in France (PQP) and in Germany (SeedGuard). The sites that are certified for the above-mentioned schemes can also be considered ESTA certified.

“The experience of AIC in the U.K. is that in responding to issues of concern to the public and politicians regarding agricultural products, we have established trade assurance schemes managed by the industry. These have allowed us to ensure they are practical and cost-effective to implement. As a result, we have avoided expensive regulations being imposed on us, and prevented many of the food safety and product security incidents occurring in the U.K.,” Wallace says.

ESTA Implementation in the EU

Within the first year of the implementation of ESTA, the number of certified sites has more than doubled. In Germany and France, the coverage in maize seed treatment is between 80 to 90 per cent and in oilseed rape between 80 to 100 per cent.

“ESA is convinced that the new national agents of ESTA in Spain and Poland will definitely support the further implementation of the scheme in these regions of Europe,” Kafka says.

“In our business, we have used ESTA certification to demonstrate [that] we apply seed treatments to the highest standard to all our seed products. Like most seed companies in the past, we [applied] seed treatment to top standards but had the occasional quality issue,” Wallace adds. “When we analysed our processes under ESTA, we found there were areas where we were not effectively monitoring and controlling some key stages and with independent audits we now have ensured the reliability of our processes.”

Schlünder would certainly recommend other companies join the ESTA system. “By any means, I recommend other companies to follow, as the ESTA scheme is a tool to [ensure] the quality of process and product; to maintain existing PPPs registered; to get new products registered; and to keep an open exchange with the authorities.”

While ESTA is off to a great start, further improvements are always necessary.

“As indicated, continuous improvement is an important pillar in the ESTA scheme. So we are working on extending the range of species covered and are adapting what we learn from the different comments from stakeholders to make the system as effective as possible,” Schlünder adds.