Chickpeas, lentils, beans, and peas are no longer just for salads and hummus – they’re the heart of a fast-growing food market, with applications now extending to items like brownies, vegan meats, and even salad dressings. Driving this transformation, researchers like Chitra Sivakumar are delving deep into the microstructure of pulse flours to open new possibilities for plant-based foods.

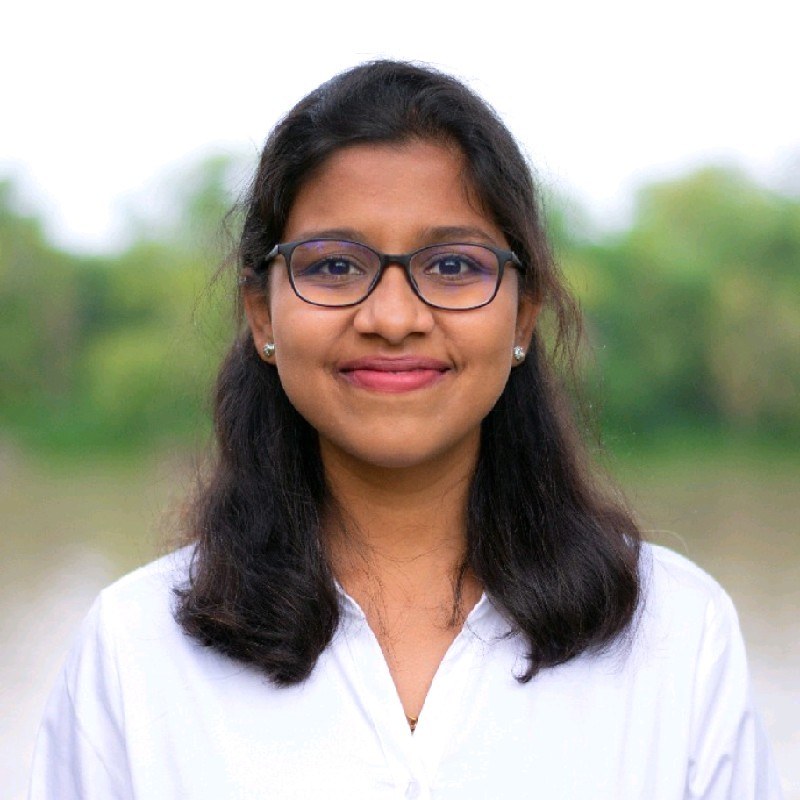

“My goal is to create something specific – a tailored flour for a particular product,” says Sivakumar, whose doctoral work on pulse flours was supervised by Dr. Jitendra Paliwal at the University of Manitoba’s Grain Storage Research Lab. Her study analyzed how factors like particle size, protein, and starch in milled pulse flours impact the final product’s quality. While rice and wheat flours have benefited from centuries of research standardizing their milling processes, pulse flours haven’t received the same level of attention.

Consumers and food producers are drawn to pulses for their high fiber and protein content, as well as their environmental benefits, Sivakumar notes. According to Pulse Canada, growing 10 million acres of pulses could capture 4.1 million tonnes of CO₂ annually – equivalent to the emissions from around 1.2 million passenger vehicles.

“More consumers want to shift to pulse-based proteins over animal-based options, but grocery stores offer limited choices,” Sivakumar adds. To help fill that gap, she’s conducting advanced research at the Canadian Light Source (CLS) at the University of Saskatchewan, supported by the Canadian Pulse Science Research Cluster.

With her colleagues, Sivakumar has examined over 60 pulse flours to understand the impact of milling on their properties. Using the synchrotron’s ultrabright light, they observed how starch and protein structures are altered through milling, analyzing the texture and distribution of particles at a molecular level – beyond the surface to the very core.

“These findings are applicable both to agricultural production and to refining milling processes for pulse flours,” Sivakumar explains. Her insights into starch and protein content can guide crop selection for specific uses, while her research on particle size can help optimize milling methods.

“We were fortunate to have access to such an advanced facility. The level of detail and accuracy it provides is truly remarkable,” she says.