New Protocols for Seed Treatment Stewardship

CropLife Canada implements new protocols for seed treatment stewardship.

During the past several years, seed treatments have come under increased scrutiny from the pollinator community and other groups outside of agriculture. Some countries, such as those in the European Union, have placed a two-year moratorium on the sale of seed treatments containing neonicotinoids — clothianidin, imidacloprid and thiamethoxam.

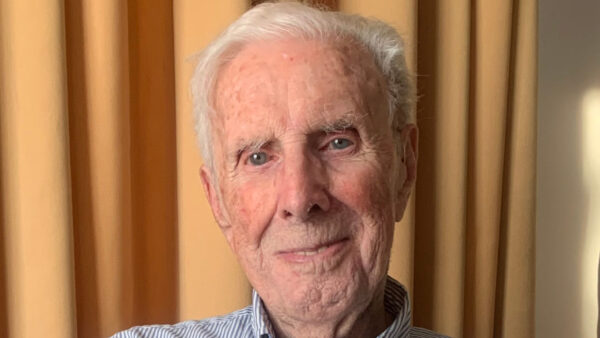

However, the seed and crop protectant industries argue that it’s more detrimental to the environment to discontinue the use of seed treatments. For example, Jon Entine, founder and director of the Genetic Literacy Project, explains that European growers are now forced to use pesticides that are “demonstrably worse” for the environment than neonicotinoid seed treatments.

Seed treatments are defined as the application of biological organisms and chemical ingredients to seed to suppress, control or repel plant pathogens, insects and other pests that attack seedlings or plants.

“There’s only so much growers can do above ground,” says Kevin Brost, FMC global director of seed treatment. “If you put 100 seeds in the ground, you want 100 plants to emerge. You don’t have a chance if they don’t come out of the ground. Seed treatments protect the seed when it’s most vulnerable.”

New protocols for handling seed treatments are designed to help improve product stewardship.

Brost says companies developing seed treatments have spent a great deal of time working on formulations that get good coverage and stay put. “We’re starting with a low amount of active ingredient and then doing a good job of keeping it on the seed,” he says.

To help educate those involved in storing, applying and using seed treatments, a number of organizations have developed seed treatment stewardship protocols or guidelines.

For instance, the American Seed Trade Association worked with CropLife America to develop the Guide To Seed Treatment Stewardship, which promotes the safe handling and management of treated seed.

Along that same principle, CropLife Canada, which represents Canadian developers, manufacturers and distributors of pest control products and seed treatments, has also worked to develop a set of auditable seed treatment standards.

Paving a Path to Sustainable Use

“These new protocols or standards are designed to be consistent with industry’s commitment to life cycle stewardship and establish clear and consistent environmental, health and safety standards,” says Russel Hurst, CropLife Canada executive director of sustainability and stewardship. “With these protocols, we’re looking to improve consistency and predictability within the regulatory and registration process; therefore, increasing access to new technology.”

In 2009, when CropLife Canada began this project, members knew it was critical to the success of the program that they collaborate with regulators and engage stakeholders throughout the value chain. They put together a multi-stakeholder committee, which included developers, retailers and seed industry members, as well as representation from government.

“Our goal was to develop standards that were practical, doable, implementable and that met the needs of regulators and the overall industry,” Hurst says.

The new protocols focus on seed treatment storage and the process used to apply the seed treatment, but not the storage, transport or handling practices after the seed has been treated, according to Hurst. The protocols apply to indoor, exterior and mobile seed treatment operations.

Today, Hurst reports that 76 audit protocols, which have been approved by CropLife Canada’s board of directors, exist. However, he says that not all of the protocols are new. “Of the 76 protocols, 66 are existing regulations that have to do with fire, building and labour codes,” Hurst explains. “The remaining 10 protocols are industry best management practices that we felt warranted inclusion in the protocols. We are finding through our beta audits that about two-thirds of the protocols are applicable to any one operation.”

The protocols are divided among seven categories — siting and exterior requirements, building structure and equipment, operations, training, documentation, employee knowledge and emergency response. Within each of those categories, protocols can be mandatory, scored and recommended.

For example, Hurst says that under the siting and exterior requirements category, there are eight protocols, of which three are mandatory and five are scored. “The scored items are very important, but in some cases, depending on the operation, they might choose to abide by the standards or lose the points available,” Hurst explains. “We’ve tried to build some flexibility into the model for people going through this process. They need to capture 80 per cent of scored items to pass the audit.”

Additionally, Hurst says that there are some grandfather clauses for existing facilities under the siting and exterior requirements category. For example, Hurst says that if an existing facility is located in a flood plain or near an open body of water, they won’t be asked to move it but new facilities would not be able to locate there. “We just ask that they have protocols in place to mitigate any environmental consequences if an event were to happen,” he says.

Currently, members of CropLife Canada can designate seed treatment products and the companies or individuals who handle them to complete a third-party audit on a two-year basis. While businesses can begin implementing the protocols immediately, the first official audit won’t take place until 2017.

A Route for Success

“By stretching this into a three-year implementation, it gives people an opportunity to familiarize themselves with the protocols and get accustomed to a new process. Essentially, the facility will be audited against the protocols,” Hurst explains, noting that companies can get a jump-start by going through a beta audit. “The facility will be provided an audit score, highlighting any deficiencies. This gives the company an opportunity to make corrective measures prior to the 2017 audit.”

According to Hurst, CropLife Canada will cover the costs of all beta audits performed through March of 2015. All beta audits performed after that will be at the expense of the seed treatment facility. On average, an audit should take three hours and cost $400.

To date, 31 auditors from the Agrichemical Warehousing Standards Association and the Canadian Seed Institute have been nationally approved to audit businesses wishing to handle designated seed treatment products to the new protocols.

Hurst adds that existing provincial regulations and other auditing activities will be taken into account with protocols that will be deemed as equivalent, such as the Alberta Seed Treatment Certification, AWSA standards and provincial training programs.

Come 2017, this will be a mature program. If a seed treatment facility has not been accredited for crop year 2017, that facility will not be able to handle designated seed treatment products. The audit process will be managed, delivered and enforced through a no-ship policy by AWSA in a similar manner to the AWSA chemical warehouse and anhydrous ammonia fertilizer stewardship programs. All accredited operations will be assigned a certified site number, which will be made available on AWSA’s website.

In speaking to industry groups about the Accredited Seed Treatment Operations Standards, Hurst says that he’s received positive and challenging feedback. “It is change and change brings apprehension,” he says. “Seed treatments are a growing aspect of the seed and ag chemical industries, so it’s an evolution. We saw an opportunity to increase the stewardship of our products; I think everyone sees the value in where we are going.

Monica Klaas, general manager for the Association of Alberta Coop Seed Cleaning Plants, says that the new protocols do increase costs and add more red tape to process, but it is a step forward. “As an industry, we now have to think about our ‘social license’ to operate,” Klaas says. “While most operators are doing an excellent job of product stewardship, there is typically room for improvement. It’s probably a short-term pain for a long-term gain.”

“If we can come together and link arms, in a way, we can set our own product stewardship destiny,” Hurst says.

Julie Deering

|

For a list of seed treatment facility auditors, |