A vegetable-picking robot that uses machine learning to identify and harvest a commonplace, but challenging, agricultural crop has been developed by engineers.

The ‘Vegebot’, developed by a team at the University of Cambridge, was initially trained to recognise and harvest iceberg lettuce in a lab setting. It has now been successfully tested in a variety of field conditions in cooperation with G’s Growers, a local fruit and vegetable co-operative.

Although the prototype is nowhere near as fast or efficient as a human worker, it demonstrates how the use of robotics in agriculture might be expanded, even for crops like iceberg lettuce which are particularly challenging to harvest mechanically. The results are published in The Journal of Field Robotics.

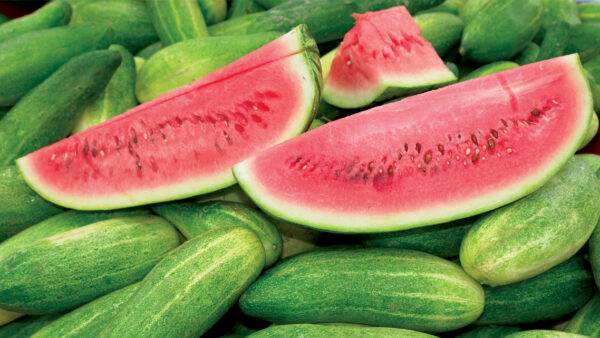

Crops such as potatoes and wheat have been harvested mechanically at scale for decades, but many other crops have to date resisted automation. Iceberg lettuce is one such crop. Although it is the most common type of lettuce grown in the UK, iceberg is easily damaged and grows relatively flat to the ground, presenting a challenge for robotic harvesters.

“Every field is different, every lettuce is different,” said co-author Simon Birrell from Cambridge’s Department of Engineering. “But if we can make a robotic harvester work with iceberg lettuce, we could also make it work with many other crops.”

“At the moment, harvesting is the only part of the lettuce life cycle that is done manually, and it’s very physically demanding,” said co-author Julia Cai, who worked on the computer vision components of the Vegebot while she was an undergraduate student in the lab of Dr Fumiya Iida.

The Vegebot first identifies the ‘target’ crop within its field of vision, then determines whether a particular lettuce is healthy and ready to be harvested, and finally cuts the lettuce from the rest of the plant without crushing it so that it is ‘supermarket ready’. “For a human, the entire process takes a couple of seconds, but it’s a really challenging problem for a robot,” said co-author Josie Hughes.

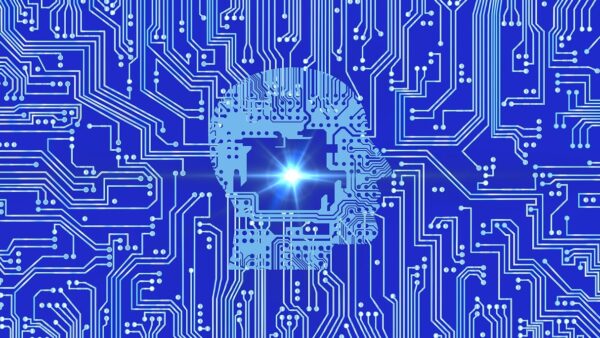

The Vegebot has two main components: a computer vision system and a cutting system. The overhead camera on the Vegebot takes an image of the lettuce field and first identifies all the lettuces in the image, and then for each lettuce, classifies whether it should be harvested or not. A lettuce might be rejected because it’s not yet mature, or it might have a disease that could spread to other lettuces in the harvest.

The researchers developed and trained a machine learning algorithm on example images of lettuces. Once the Vegebot could recognise healthy lettuces in the lab, it was then trained in the field, in a variety of weather conditions, on thousands of real lettuces.

A second camera on the Vegebot is positioned near the cutting blade, and helps ensure a smooth cut. The researchers were also able to adjust the pressure in the robot’s gripping arm so that it held the lettuce firmly enough not to drop it, but not so firm as to crush it. The force of the grip can be adjusted for other crops.

“We wanted to develop approaches that weren’t necessarily specific to iceberg lettuce, so that they can be used for other types of above-ground crops,” said Iida, who leads the team behind the research.

In future, robotic harvesters could help address problems with labour shortages in agriculture, and could also help reduce food waste. At the moment, each field is typically harvested once, and any unripe vegetables or fruits are discarded. However, a robotic harvester could be trained to pick only ripe vegetables, and since it could harvest around the clock, it could perform multiple passes on the same field, returning at a later date to harvest the vegetables that were unripe during previous passes.

“We’re also collecting lots of data about lettuce, which could be used to improve efficiency, such as which fields have the highest yields,” said Hughes. “We’ve still got to speed our Vegebot up to the point where it could compete with a human, but we think robots have lots of potential in agri-tech.”

Source: University Of Cambridge