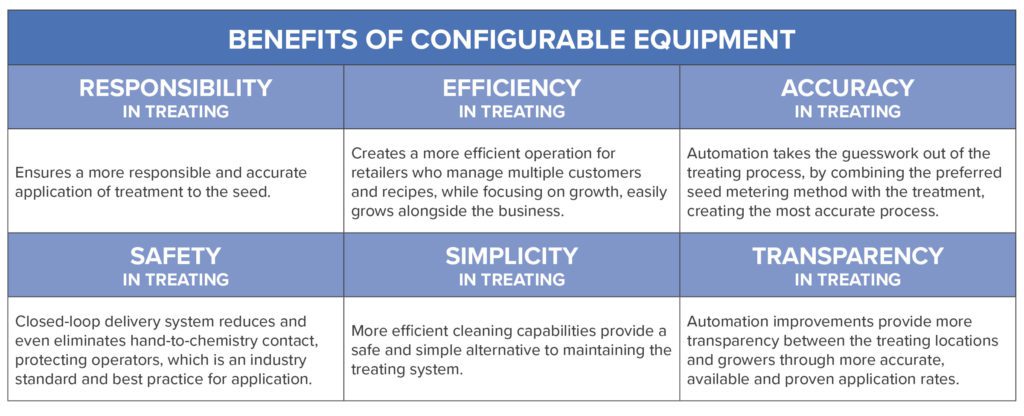

Increase operational ROI with configurable equipment, and the benefits don’t stop there.

Seed and treatment companies agree that accuracy, efficiency and consistency during each run are the most important factors when considering seed treating and handling equipment purchases. There are two options to consider: configurable and non-configurable equipment. The difference?

Configurable equipment grows alongside the operation as the business grows, increasing the overall return on investment, whereas non-configurable equipment has a shelf life, it does not grow along with the business, and quickly outdates the operation, creating a more costly situation.

USC is the only manufacturer to provide completely configurable treating equipment. The options are endless and catered directly to each operation, streamlining the process and providing exactly what the customer needs to achieve operational goals. The benefits of configurable equipment far outweigh the alternative, making the decision for operators an easy one.

As the business grows, and new advancements in applications are continually introduced to the market, so are the capabilities of configurable equipment.

Efficient, safe, simple, accurate and affordable are a few reasons configurable equipment is preferred, and why it has become the industry’s standard.

Andy Renyer USC, LLC

Co-Founder, Director of Sales & Marketing

• With his brother, started USC, LLC in 1999 trailing a single treater across the country.

• Became industry’s treating equipment expert, growing internationally with more than 5,000 customers.

• Developed strategic alliances with global corporations to bring treating technology to downstream market.