Each year EU imports more than 11 megaton soy protein from US and South America, worth $3.8 billion USD for its pig- and poultry production. Can this be changed to a greener, local and yet just as economical home production?

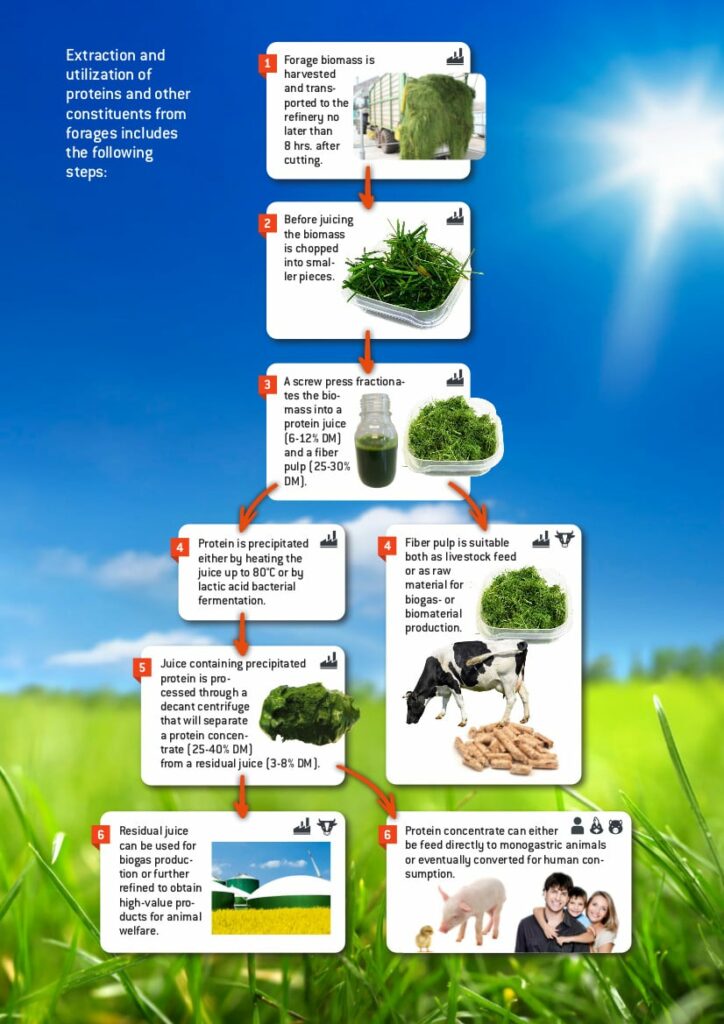

That’s a big and highly relevant question as EU is pushing its member states to implement any measure that can minimize agriculture’s greenhouse gas emissions. Extracting proteins from forage grasses and legumes is possible (see illustration for details) and it does indeed represent a more climate- and environmental solution, as grass and legumes are perennial high yielding crops in protein output and carbon sequestration. The catch, however, is to make it in a profitable way.

Preliminary calculations indicate that forage-based proteins already today represent an attractive alternative for organic meat producers, due to high international prices on organic soy. When it comes to conventional farming there are still a number of factors that needs to be optimized before a convincing competition with imported soy can be realized. Several of these factors are now being addressed in a number of Public Private Partnership projects both at the national- and at the EU-level.

First, the process should rely only on forage varieties with maximum protein yield. In this regard, DLF will head the tests of more than 400 grass- and clover varieties in a major Danish research project called GrassPro. The aim is to select 50 varieties with the highest protein yield- and quality. Selected varieties will be also be measured for digestibility to ensure that pulp from the refinery process is well-suited for silage- and/or biogas production. Outcome will allow researchers and product managers to formulate grass mixtures with maximum protein yield for different soil types. To ensure continuous operation of refinery plants over the year mixtures should preferably comprise a selection of very early to very late material. During winter, when there are no fresh forages, refineries should extract protein from other sources such as seaweed and starfish.

Second, new harvesting equipment and machines to handle the forage grass at the refineries need to be developed so quality and extractability is not compromised during harvest or transport to the refinery. This challenge will be addressed by farm machine manufacturers and researchers who will test specialized harvesting machines and pre-extraction treatments.

Third, by-products from the refinery needs to be utilized more efficiently, and researcher will investigate how high-value constituents, which has health promoting effects can be retrieved from residual fractions. There are even initiatives to investigate how green proteins can be used directly for human consumption, as their amino acid composition seems to represent human needs quite well. GrassPro includes four Danish universities, one branch organization, as well as a number of industrial stakeholders. It will run over the next four years and is by far the largest screening project for forage-based proteins.