Collaboration, innovation and high process standards are helping S&W Seed deliver new alfalfa genetics to the industry.

Capturing the gamut of production, S&W is one of only three companies producing genetics for the alfalfa industry and helping to deliver the production advantages the market demands. With production of both dormant and non-dormant seed varieties in North America, Australia and Europe, S&W is using their strategic “Produce to Plan” seed production model to produce varieties that fill customer demand.

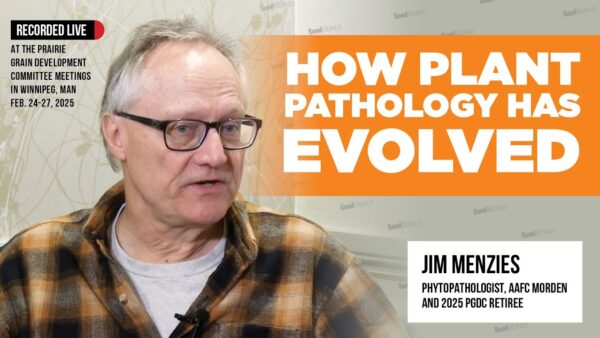

Alfalfa seed production isn’t without its challenges, however, as notes Kirk Rolfs who serves as vice president of Supply Chain Management for the company.

“Taking what a plant breeder creates and ensuring that the product traits reach the customer at the end of the chain is no small task. We go through rigorous selection and breeding activities to produce a new variety,” he shares.

Variety Advancement

Recently opened, the Nampa, Idaho breeding location focuses on seed production research: conducting greenhouse crosses and cage production, while focusing on stem nematode and the aphid complex; with efforts concentrated on developing market-specific varieties.

Through bumble bee pollination, alfalfa plants in the greenhouses are crossed, creating both the opportunity for the plants themselves to be transplanted, as well as the seed the plants produce to be planted. Depending on which type of trait: parent-plant or backcrossed, the market is looking for, those seeds or plants are grown in caged production.

“At any given time, there may be several hundred potential varieties in our research system and they are all being evaluated. Some rise to the top as true candidates for new varieties,” says Rolfs.

Selection throughout the germplasm and the presentation of those varieties’ data through a series of advancement meetings with S&W’s salesforce determines which varieties advance to pre-commercial status through caged production.

Creating New Commercial Varieties

Screened cages 20 feet wide, 30 feet long and six feet high are constructed to control pollen flow, with each cage representing a potential new variety of seed. In a typical year, the location will see in the neighborhood of 90 cages constructed and populated, representing the full breadth of both traited and non-traited S&W germplasm and all dormancies. At the end of the growing season, the tops are removed from the cages and the plant is allowed to dry so seeds can be hand-thrashed. The produced seed is known as breeder seed and is the basis of the commercialization of every new variety.

Each variety needs to yield a target number of pounds of breeder seed to ensure enough seed exists for advancement through planting stock establishment, registration and university trials.

Foundation fields are planted with breeder seed, to establish a planting stock for commercial production; a portion of the breeder seed may also go into registration trials, while additional pounds may be allocated to university trials for the establishment of third-party data.

Working Together

Rolfs notes that while there is a very small number of companies supplying the germplasm for the entire alfalfa industry, the cooperation and professional courtesies involved in the production of alfalfa seed are unparalleled.

“Our industry, as a whole, takes great care in producing seed at a commercial level. We all have to coexist in the production environment. We are all competing but we all work very well together, which is really important because at the end of the day, you can’t control where a bee flies.”