It’s a brave new world in the realm of seed analysis.

On July 8 — the opening day of the Seeds Canada conference in Edmonton, Alta. — SGS Canada Crop Science welcomed nearly 20 industry leaders to an exclusive tour of its Sherwood Park lab that highlighted how new technologies are redefining seed analysis and beyond.

At the forefront of these innovations is artificial intelligence (AI).

“Artificial intelligence, encompassing machine learning and image analysis, is redefining what we do in our field,” said Trevor Nysetvold, director of crop science at SGS Canada.

“We are on the cusp of implementing this technology to enhance what we do and have become known for.”

Janek Bartel, lab manager at SGS Canada, highlighted the integration of AI and machine learning (ML) in seed testing. Key points included the use of machine learning for image analysis and seed sorting, the application of decision trees and random forests, and the role of regression analysis in predictions. He also discussed various AI models, including their limitations and the need for high-quality background data.

The use of AI in plant purity analysis and optical sorters was demonstrated, emphasizing the importance of human oversight for accuracy.

“Technology is a powerful tool, but of course we need talented people behind the scenes to bring that human touch to it,” Bartel said.

The tour also spotlighted the role of robotics in SGS’s operations.

Two years ago, the lab acquired a machine called the QIAcube HT, which handles most of its DNA extraction work. This machine has an innovative design with a pipette arm that can attach eight tips at once, significantly speeding up the process. The reagents come in long rows, allowing all eight tips to aspirate and dispense simultaneously. It has its own vacuum apparatus to handle liquid waste, making the whole process much easier.

The QIAcube HT is user-friendly and connects to a computer with a program that calculates the number of reagents needed based on the number of samples, said Annu Albert, plant pathology and molecular biology technician.

“Until two years ago, I did most things manually. A single batch of 23 samples took about two-and-a-half hours, involving a lot of repetitive pipetting, which strained our arms and thumbs. During busy seasons, we sometimes had to do three to four batches a day, alternating between two people to manage the workload,” Albert said.

This manual process was not only tiring, but also prone to errors due to fatigue and inconsistencies in pipetting.

She can now process 43 samples at once. It takes about two and a half hours, but staff needs to be there for only the first hour. After setting it up, she can focus on other tasks, which frees up a lot of her time for analysis and other work.

“This machine not only doubles our capacity but also reduces the physical strain and potential for errors, making our work much more efficient and accurate.”

“We follow the old adage: if it’s dull, dirty or dangerous, it’s prime for automation,” Nysetvold explained. This approach not only boosts efficiency but also aligns with SGS’s commitment to sustainability by minimizing human exposure to hazardous chemicals.

SGS is pushing the envelope further by expanding its analytical chemistry services.

“This expansion into the analytical chemistry side of the business allows us to offer even more comprehensive services to our clients,” Nysetvold added.

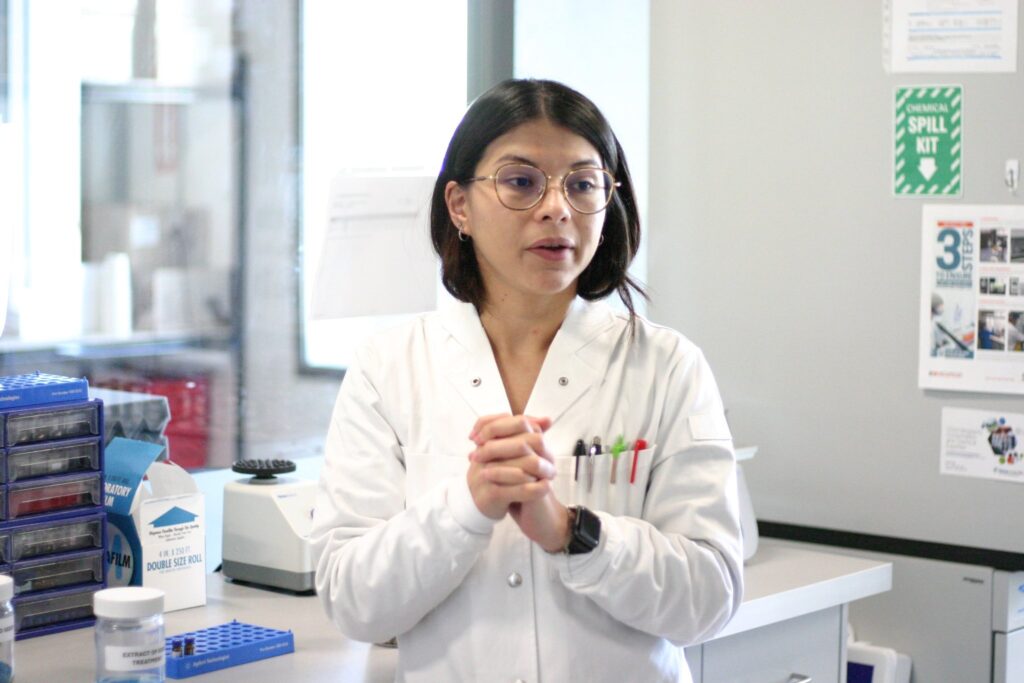

High-Performance Liquid Chromatography (HPLC) stands at the heart of these services, said Daniela Guaqueta, analytical chemistry technologist. She walked attendees through the HPLC process, a sophisticated technique that separates and quantifies active ingredients in seeds. This method is essential for understanding seed treatments and predicting crop success, providing growers with invaluable insights.

Chlorophyll content analysis and dust-off tests are also critical for assessing seed health and environmental impact.

“These techniques provide us with the data we need to improve agricultural practices and enhance crop production,” Guaqueta said. “By understanding the intricacies of seed composition, we can help farmers achieve better yields and ensure the sustainability of their crops.”

The North American seed industry is synonymous with innovation, and SGS is committed to keeping pace, Nysetvold added.

“Quality is crucial for all products, and our role is to provide the highest level of quality assurance and qualitycontrol. As the industry evolves, so too must the technologies used to test and assure the quality of seeds.”